Rainy season server guarding guide

As humidity rises, hidden dangers emerge. For servers safeguarding critical enterprise data and business operations, the high-moisture environment of the rainy season poses an invisible threat to stable performance. Among these, oxidation risks for server motherboards and power supplies are particularly pronounced. A single instance of condensation can corrode contacts, cause circuit shorts, and trigger a chain reaction of service outages and data loss.

The Oxidation Crisis: Why Is the Rainy Season a “High-Risk Period” for Server Components?

The core threat of the rainy season lies in persistently high relative humidity (often exceeding 80%). When servers transition between operational and shutdown states, significant internal temperature fluctuations occur. After powering down, components like motherboards and power supplies rapidly cool. This rapid cooling attracts moisture from the air, causing it to condense into invisible droplets on precision circuit boards and metal pins. These droplets are the primary culprits accelerating metal oxidation and electrolytic corrosion.

Motherboard: The server's “nerve center,” densely packed with copper circuits, memory slots, and chip solder joints. Once oxidized, signal transmission becomes completely obstructed.

Power Supply: The server's “power heart.” Its internal capacitors, transformers, and terminals are highly sensitive to humidity. Oxidation directly causes unstable power delivery or even burnout.

Motherboard Moisture Protection: Blocking Oxidation Pathways at the “Nerve Endings”

Motherboard oxidation is not an instantaneous event; it progresses gradually from “contact corrosion” to “circuit failure.”

Core Risks:

Signal Transmission Interruption: Non-conductive oxide films forming on metal contacts like memory slots and PCI-E slots can directly cause device recognition failures and frequent blue screen reboots.

Circuit Short-Circuit Burnout: Rust particles from oxidation can form “leakage bridges” between adjacent circuits, causing minor chip damage or total motherboard failure.

Chip Performance Degradation: Corrosion of solder joints on core chips like the southbridge and northbridge leads to unstable power supply and significant performance decline.

Comprehensive Protection Measures:

Environmental Humidity Control (Root Cause Solution): Server rooms must be equipped with precision air conditioning or professional dehumidifiers to strictly maintain humidity within the optimal range of 40%-60%, eliminating oxidation conditions at the source.

Thorough Cleaning (Routine Maintenance): Every 1-2 months, use a dry soft-bristle brush to remove dust accumulation from the motherboard (dust acts as a moisture adsorbent). If minor oxidation is detected, gently wipe contacts with a cotton swab dipped in anhydrous alcohol. Allow thorough air-drying before powering on.

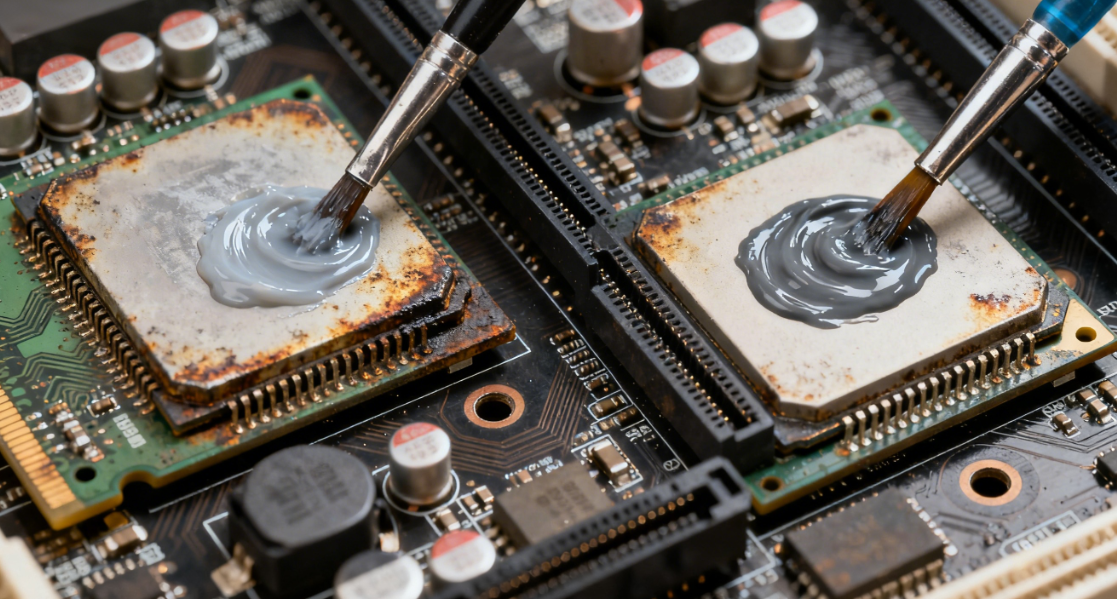

Technical Enhancement (Proactive Protection): In high-humidity environments, apply a thin layer of conductive paste to critical interfaces like memory slots. This insulates against moisture while maintaining electrical conductivity. Additionally, selecting dust-proof and moisture-resistant server enclosures provides effective physical isolation from external humidity.

Power Supply Moisture Protection: Safeguarding the Stable Output of the Server's “Power Source”

Oxidation risks in power supplies are more “destructive,” often directly causing server failure at the power supply level.

Primary Hazards:

Capacitor Bulging and Leakage: Electrolytic capacitor leads are particularly prone to oxidation. Corrosion causes abnormal charging/discharging, temperature spikes, eventual bulging and leakage, resulting in severe voltage fluctuations that damage motherboards and hard drives.

Poor Terminal Contact: Oxidation on 24-pin motherboard power connectors and SATA ports increases resistance, manifesting as unresponsive server boots or sudden shutdowns during operation—often causing hard drive data loss.

Professional Protection Solutions:

Condition Monitoring & Ventilation: Regularly inspect the power supply interior for moisture condensation or dust accumulation. Ensure chassis fans operate normally to dissipate internal humidity via airflow. For idle backup servers, power them on for 1-2 hours monthly to utilize self-generated heat for moisture expulsion.

Upgrade Moisture-Resistant Hardware: In humid regions (e.g., southern China's rainy season), strongly consider replacing power supplies with moisture-resistant coatings designed for servers. The specialized coating on internal circuits and components forms a permanent protective barrier, fundamentally enhancing oxidation resistance.

Building a Comprehensive Moisture-Proof System: The “Three Ironclad Rules” of Operations Management

Beyond targeted hardware protection, scientific operational practices are equally critical.

Maintain Stable Operation: Avoid frequent server power cycling to minimize “breathing effect” and condensation risks caused by sudden temperature changes.

Prioritize Data Backup: Before the rainy season arrives, complete dual-layer data backup (local + cloud). This ensures minute-level business recovery even in case of hardware failure.

Engage Professional Inspections: Annually before the rainy season, invite professional IT maintenance teams to conduct comprehensive server health checks. This includes using multimeters to test power supply outputs and inspecting motherboard insulation to prevent potential issues.

Protecting servers from moisture during the rainy season is a battle of foresight and execution. To counter oxidation risks in motherboards and power supplies, only through strict environmental control, meticulous daily maintenance, and forward-thinking hardware investments can you build a robust “moisture barrier.” This ensures your data fortress remains impregnable through any adverse weather. Take action now—implement professional protective measures to safeguard your business continuity.